Calculate cost

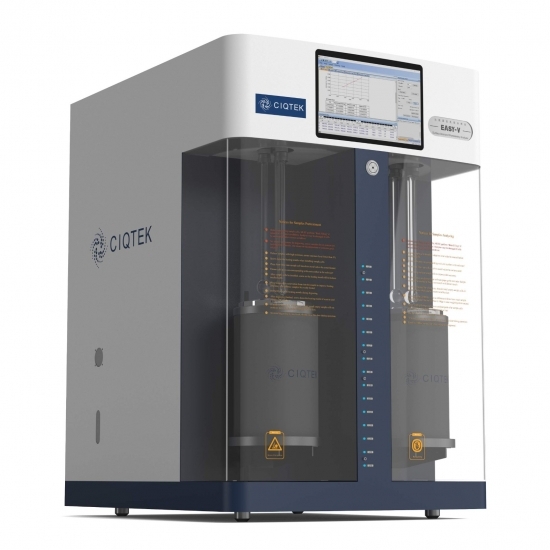

Automatic surface area and porosimetry analyzer CIQTEK EASY-V 1440

Name

E-mail

Phone number

Calculate cost

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Contact me

Name

E-mail

Phone number

Contact me

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Automatic surface area and porosimetry analyzer CIQTEK EASY-V 1440

Calculate cost

Contact me

EASY-V 1440 is a BET specific surface area and pore size analyzer independently developed by CIQTEK using the static volumetric method.

- Specific surface area testing, range 0.0005 (m2/g) and above.

- Pore size analysis: 2-500nm.

- Four analysis stations, 4 samples can be tested simultaneously.

- Equipped with a two-stage vacuum pump.

- Built-in testing computer, safe and stable. 10-inch capacitive touch screen, can be controlled by tablet.

- Built-in ball screw lifting system driven by stepper motor, eliminating the shortcomings of common screw types that are easy to jam, etc.

- The safety protection door can prevent accidents caused by accidental contact with low-temperature liquid nitrogen and eliminate the influence of environmental factors on the test.

- The 4L stainless steel inner Dewar bottle overcomes the fragile defects of glass Dewar bottle, and the high thermal insulation ensures continuous testing for more than 72 hours.

Technical specifications:

Test function:

Static volume principle, adsorption/desorption isotherm measurement, single and multi-point BET method, Langmuir method, BJH total pore volume and pore size distribution analysis, DR and DA filling theory, t-graph external surface area measurement, true density measurement; Powerful online data analysis system, as well as specific surface area and pore size distribution testing system to ensure more stable and accurate testing data.

Test ranges:

0.0005 (m2/g) ~ unknown upper limit (specific surface area); 2 nm - 500 nm.

Test accuracy:

Specific surface area repeatability error ≤±1.0%.

Sample number:

Four samples were tested at the same time, and the four samples degassing processing (optional), sample testing system and sample processing system are independent;

Testing and sample processing can be carried out simultaneously, which can avoid contamination of the testing pipeline, further ensuring the test accuracy and prolonging the service life of the instrument.

Test modes:

Integrated "Single nitrogen testing mode" and "Standard nitrogen + helium testing mode" for customers to choose according to their actual needs;

"Standard nitrogen + helium testing mode", which complies with international standards, can ensure the accuracy and consistency of the results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for determining the headspace. "Single nitrogen testing mode" can obtain the desired test results.

Introduction to Sample Degasser:

Flexibly heat samples from 25°C (77°F) to 400°C (752°F) to meet different sample processing requirements; The sample degasser can remove moisture from the sample for drying function.

During sample heating, the processing system can be further evacuated to effectively remove impurities adsorbed on the surface of sample particles and achieve cleaner material processing.

For samples that should not be exposed to air, protective gas can be introduced during processing if necessary to achieve complete isolation of the sample from air.

After sample processing, protective gas is fed into the cooling process to isolate and protect the processed sample.

For samples with large amounts of moisture and impurities on the particle surface, protective gas can be introduced under the action of air flow to achieve the function of cleaning the sample surface, which is helpful in removing impurities and moisture more quickly and thoroughly.