Main ·

Calculate cost

Waste sterilization complex

Name

E-mail

Phone number

Calculate cost

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Contact me

Name

E-mail

Phone number

Contact me

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Waste sterilization complex

Calculate cost

Contact me

Waste sterilization complex Spectromart SteRAY-MED

The complex allows sterilization to neutralize hazardous medical waste for subsequent disposal at landfills. With low energy consumption, a high level of sterility is achieved without toxic emissions into the atmosphere and toxic waste that enters the soil and water.

The Spectromart SteRAY-MED complex can be located in close proximity to residential areas to reduce the logistical shoulder.

Sterilized polymer components can be used as secondary raw materials for the production of household products.

The world practice of medical sterilization indicates the demand for this type of disinfection: an industrial installation for the radiation treatment of hospital waste based on electron accelerators with an energy of 1.5-3.0 MeV, with a power of 120 kW, is operated at the Virginia Cay waste processing plant in Miami, State Florida, USA, the volume of processing of one unit is up to 2.0 thousand tons; Radiation-technological installations based on linear electron accelerators of the "LINAK" type with an energy of 3.0-5.0 MeV are operated in Strasbourg (Centre hospitalier universitaire, France), in Italy (ENEA-Trisaia Center, Basilicata, Southern Italy), and in In Italy, out of 250 thousand tons of hospital waste, 60 thousand tons are disinfected, incl. 4.0 thousand tons - by the radiation method.

The innovation of the technology lies in its compactness, environmental friendliness and economy. The "SteRAY-MED" complex produced by OKB "Spectromart" is the result of the scientific activity of domestic physicists, it is the quintessence of nuclear technologies.

Due to the fact that they are not disposed of properly, a problem has arisen - the spread of infections, which, as a result of incorrect manipulations with waste, enter sewage and groundwater, air, and soil.

The innovation of the technology lies in its compactness, environmental friendliness and economy. The "SteRAY-MED" complex produced by OKB "Spectromart" is the result of the scientific activity of domestic physicists, it is the quintessence of nuclear technologies.

Due to the fact that they are not disposed of properly, a problem has arisen - the spread of infections, which, as a result of incorrect manipulations with waste, enter sewage and groundwater, air, and soil.

The development of the project includes carrying out design and engineering work to create a process unit based on the accelerator, creating technological documentation for the process, developing and linking the architectural and construction part of the project to a specific site.

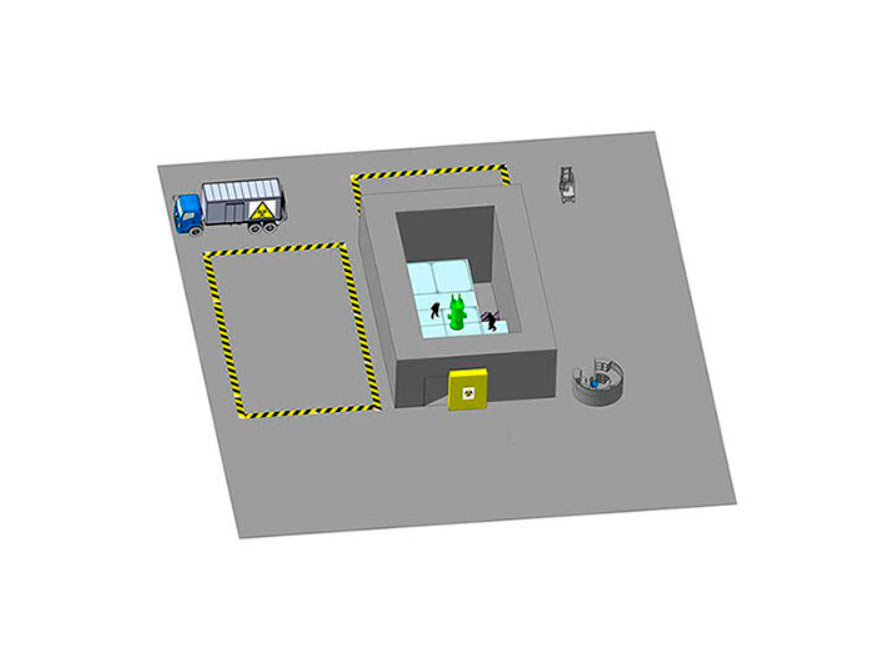

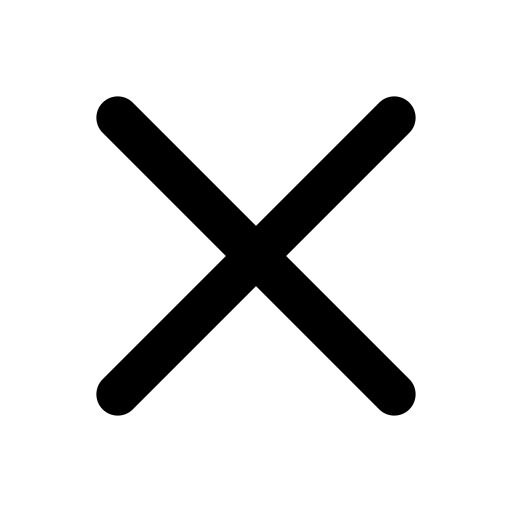

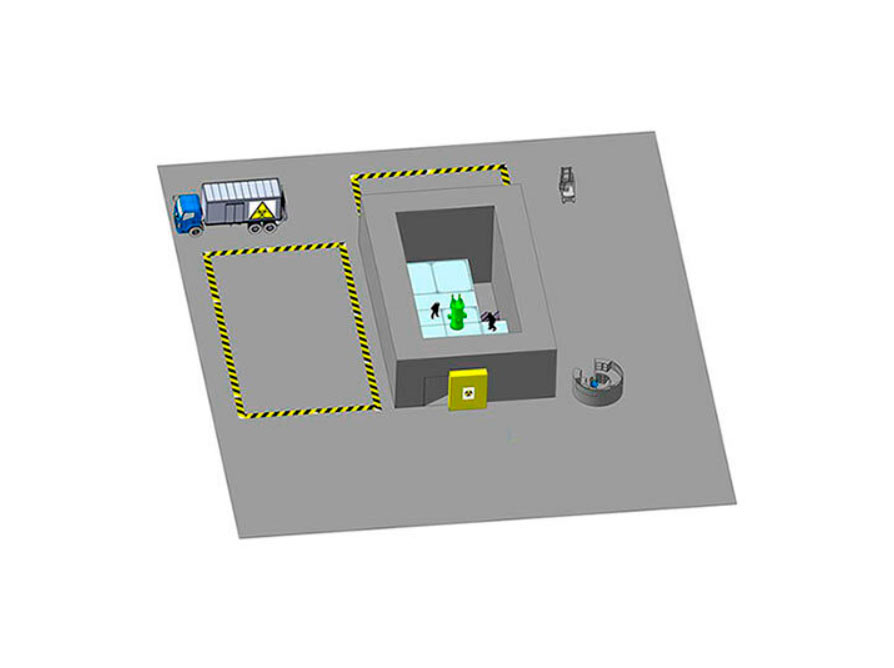

Design decision

The development of the project includes carrying out design and engineering work to create a process unit based on the accelerator, creating technological documentation for the process, developing and linking the architectural and construction part of the project to a specific site. The project implements the creation of the entire technological chain for the collection, sterilization and disposal of waste, including:

The development of the project includes carrying out design and engineering work to create a process unit based on the accelerator, creating technological documentation for the process, developing and linking the architectural and construction part of the project to a specific site. The project implements the creation of the entire technological chain for the collection, sterilization and disposal of waste, including:

- transport communication for supplying products for processing - from access roads to a conveyor line in the irradiation zone, operating on the principle of "supply-issuance";

- an irradiation zone with a placed accelerator, radiation protection, control systems of the facility and life support systems of the accelerator, control of process irradiation parameters;

- loading and storage (accumulative) zone.

Why SteRAY-MED

- High productivity and the possibility of sterilization in consumer packaging (capacity up to 10 tons per day, depending on the packaging)

- Wide range of processed products

- No costly degassing or aeration of sterilization rooms required

- Lower costs compared to other sterilization methods (gas, chemical)

- No need to unpack waste containers before processing

- Environmentally friendly sterilization method and no chemical waste

Advantages

- Safe

The complex was designed in accordance with radiation safety standards - Easy to operate

The complex is serviced by 2 specialists with secondary education: mechanic, instrumentation fitter - Effective

Low cost of processing a kilogram of products - Compact

The emitter has the smallest dimensions among analogues