Main ·

Calculate cost

Conveyor inline raw material analyzer

Name

E-mail

Phone number

Calculate cost

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Contact me

Name

E-mail

Phone number

Contact me

Manager will contact you and answer all your questions

By clicking the button, you agree to the terms of the privacy policy

Conveyor inline raw material analyzer

Calculate cost

Contact me

Conveyor inline raw material analyzer Spectromart NIR-ON

At present, our company Spektromart is developing the NIR-ON Inline Chemical Composition Analyzer. The project was started by us in 2021 and is carried out entirely at our own expense. Taking into account the circumstances on the restriction on the import of technologies to the Russian Federation, we have decided to speed up the process of developing the analyzer with the attraction of investments from outside.

At the moment, there is a pilot plant and mathematical models for various materials are being developed.

The in-line chemical composition analyzer NIR-ON is developed by Spectromart taking into account complete independence from foreign technologies, components, licenses. Our company has a fleet of production equipment (CNC machines and others) and highly qualified specialists (designers, programmers, etc.) to implement the project and launch the analyzer into mass production.

Infrared spectrometry:

Near Infrared (NIR) technology uses the entire wide range of infrared spectra that light bulbs provide. Their emitted NIR radiation (Near IR) hits the target raw material to be analyzed as it passes through the conveyor belt. This NIR radiation excites vibrations of molecular bonds in the material being tested, resulting in reflection and absorption spectra characteristic of the analyzed constituents.

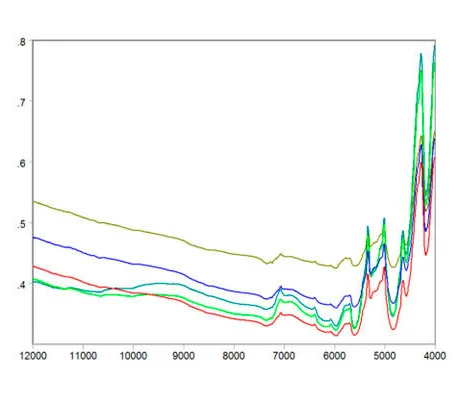

The figure shows a typical set of absorption spectra obtained from phosphate ore.

Infrared spectrometry:

Near Infrared (NIR) technology uses the entire wide range of infrared spectra that light bulbs provide. Their emitted NIR radiation (Near IR) hits the target raw material to be analyzed as it passes through the conveyor belt. This NIR radiation excites vibrations of molecular bonds in the material being tested, resulting in reflection and absorption spectra characteristic of the analyzed constituents.

The figure shows a typical set of absorption spectra obtained from phosphate ore.

Since NIR technology obtains chemical information from the molecular bonds of mineral phases or molecules, the SpectraFlow analyzer provides exceptionally accurate results for all components, regardless of their periodic number. Molecules such as moisture or other organic components can be measured directly next to inorganic compounds with very high accuracy.

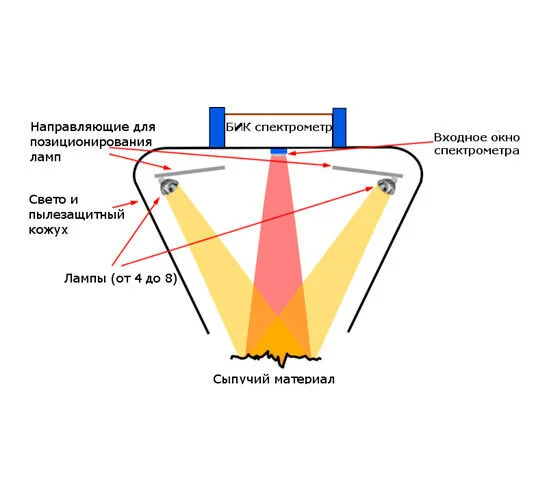

The full NIR spectrum required for online chemical analysis is provided by a set of light sources. These lights emit infrared radiation which is used for analysis. The infrared light reflected by the moving bulk material is collected by a Fourier Transform Infrared (FTIR) spectrometer at the center of the illumination system.

An FTIR spectrometer is used to detect absorption spectra. Its main advantage is that it determines each individual spectrum in one step. This means that it is very stable and the model calibration can be easily transferred from one spectrometer to another.

The FTIR spectrometer used can use much more reflected NIR radiation than the standard Dispersive NIR Spectrometer and is extremely mechanically robust. The FTIR spectrometer has no internal moving parts, making it even more stable and reliable. This feature ensures extremely stable measurement performance and reduces the need for external calibration to a maximum of four times per year, which is necessary only because the change in the intensity of the light spots must be compensated for.

The full NIR spectrum required for online chemical analysis is provided by a set of light sources. These lights emit infrared radiation which is used for analysis. The infrared light reflected by the moving bulk material is collected by a Fourier Transform Infrared (FTIR) spectrometer at the center of the illumination system.

An FTIR spectrometer is used to detect absorption spectra. Its main advantage is that it determines each individual spectrum in one step. This means that it is very stable and the model calibration can be easily transferred from one spectrometer to another.

The FTIR spectrometer used can use much more reflected NIR radiation than the standard Dispersive NIR Spectrometer and is extremely mechanically robust. The FTIR spectrometer has no internal moving parts, making it even more stable and reliable. This feature ensures extremely stable measurement performance and reduces the need for external calibration to a maximum of four times per year, which is necessary only because the change in the intensity of the light spots must be compensated for.

| X-Ray Fluorescence Analysis (XRF) | Instant Gamma Neutron Activation (PGNAA) | NIR-ON Near Infrared Spectrum Analyzer | |

| Measuring method | Offline | Online | Online |

| Purpose of measurements | Quality control DIN/ASTM | Process control, directions | Process control, directions |

| Practical costs | Medium | High | Low |

| Analytical basis | Electronic shells | Nuclei | Molecules and minerals |

| Element range | Calibration dependent: F (WDX) or Na (EDX) | From Na or from O (neutron tube) | All elements, including hydrogen, humidity |

| Analysis time | 40-60 minutes | Average | 240 measurements per minute |

| Safety | X-rays. Requires a license, constant monitoring by authorized bodies. The conveyor is broken. Dangerous for health | Ionizing radiation. Requires a license, constant monitoring by authorized bodies. The conveyor is broken. Hazardous to health | No radiation exposure, no permit required. Safely |

| Analytical Accuracy | High | From high to low (depending on the element) | High |